We cover following Industries: automotive, marine, medicine, aerospace and robotics.

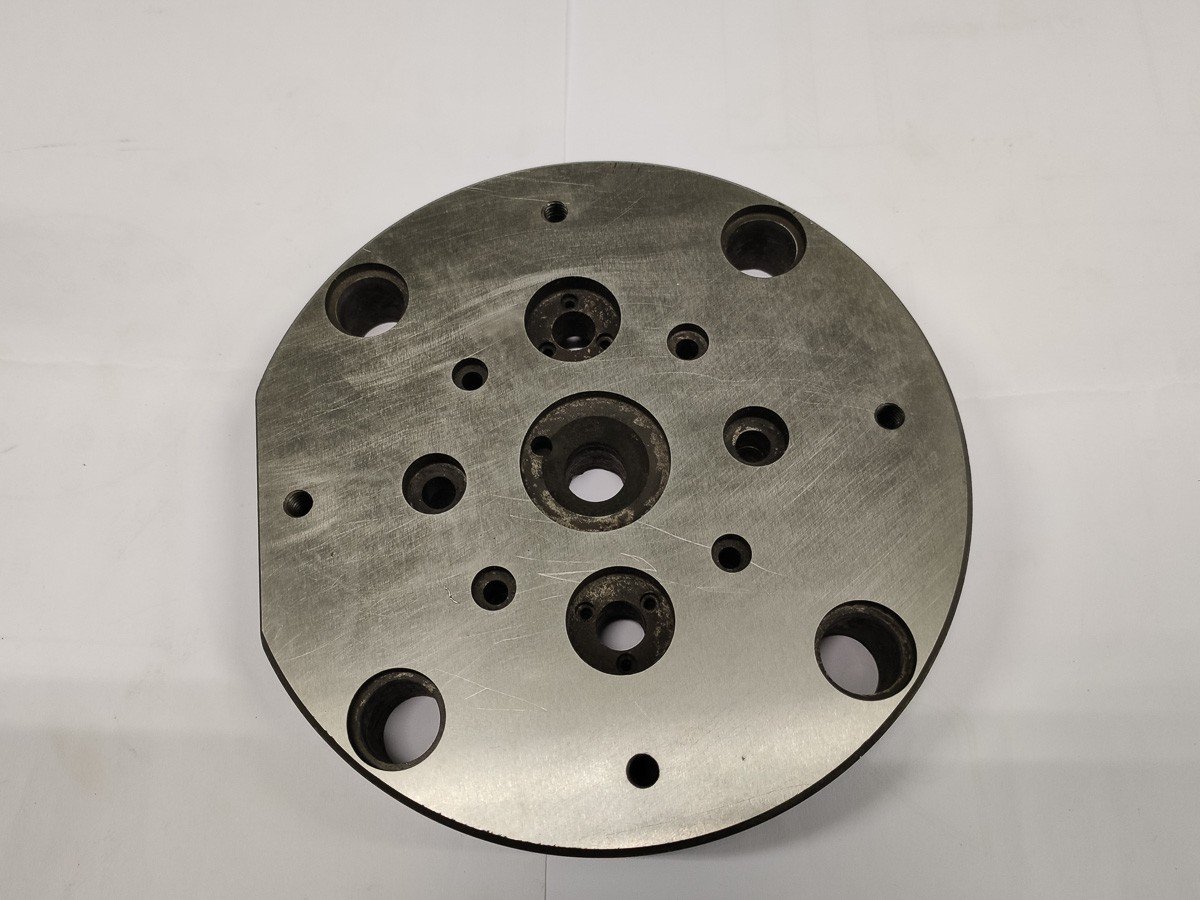

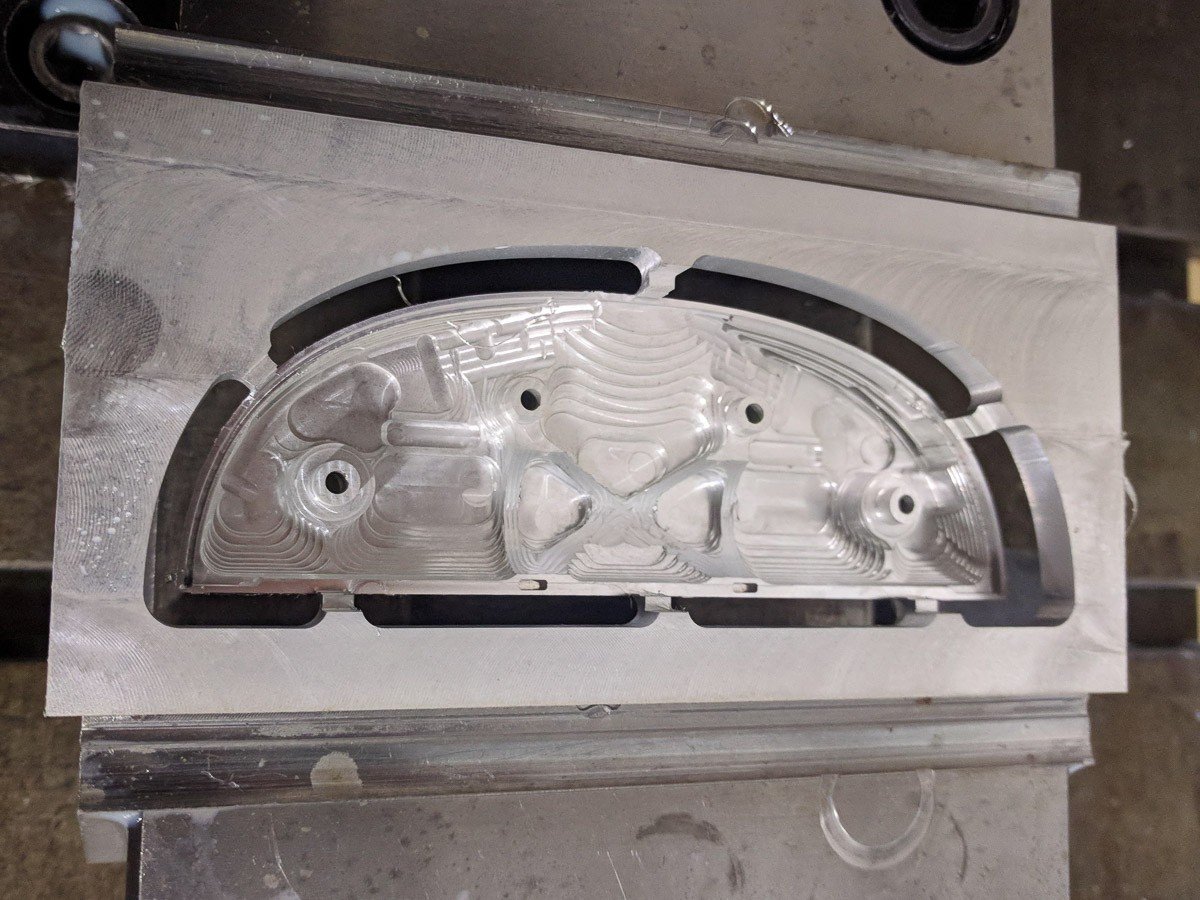

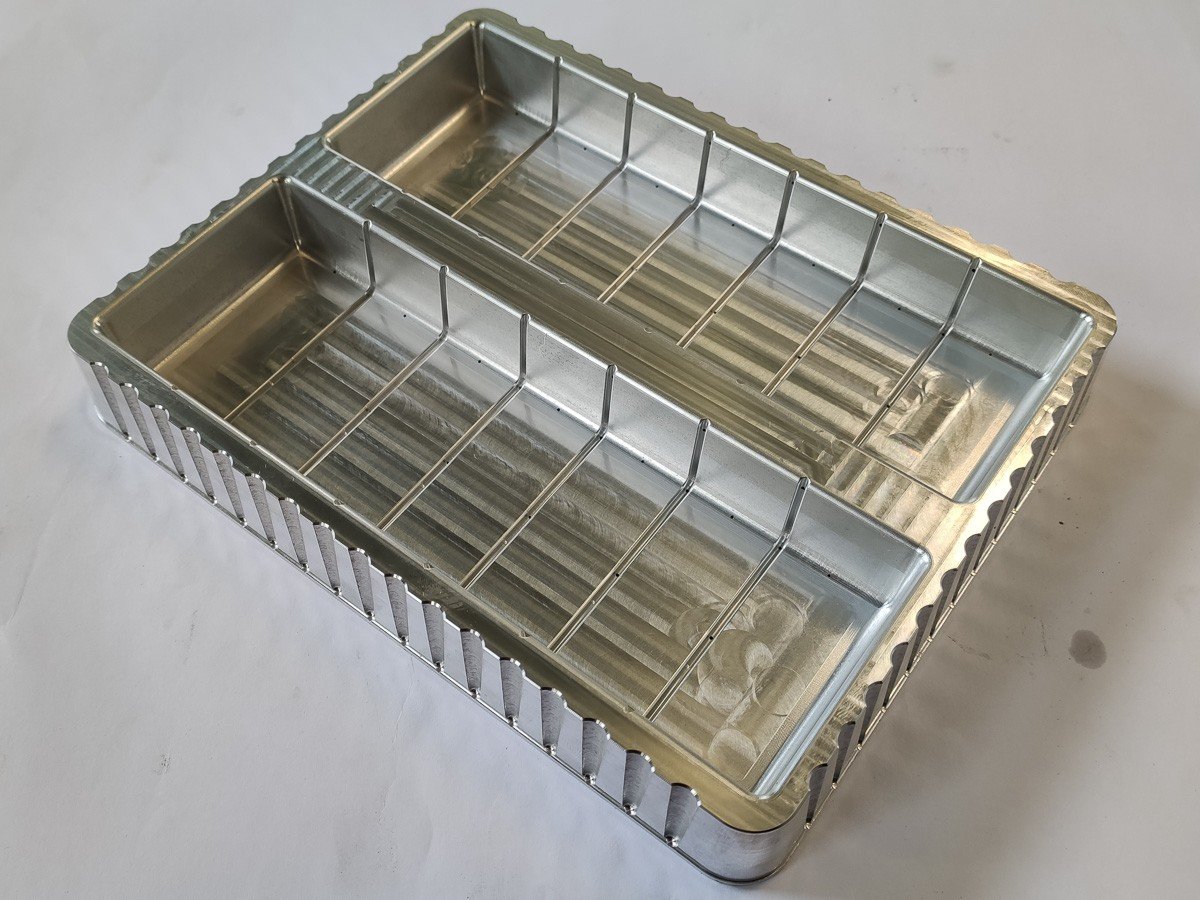

We offer production of parts with different design: heavy or lightweight parts, dies and molds or thin-walled enclosures and structural components.

Accuracy

The general accuracy for CNC milled parts is upto 0.01mm. But we can achieve 0.005mm and higher accuracy with customer support when part design is well explained and measuring technology is considered.

Commonly used materials

- Steel (C45, S235, S355)

- Tool steel (SAE 4340, SAE 4140, 1.7225, 42CrMo4, SCM440, 36CrNiMo4, 1.6511, EN24 and etc)

- Stainless Steel (AISI 304, AISI 303, AISi 316, AISI 420 and etc)

- Aluminum (2xxx, 6xxx, 7xxx series, mostly used EN AW 6082-T6 and etc)

- Bronze (CuAl10Fe5Ni5, Rg7, CuSn12 and etc)

- Magnesium (AZ31B)

- Titanium (Ti-6Al-4V)

- Plastics (Polyurethane (PU), Polyacethal (POM), Polytetrafluoroethylene (PTFE) (Fluoroplast), Polyetheretherketone (PEEK) etc

Technical capabilities

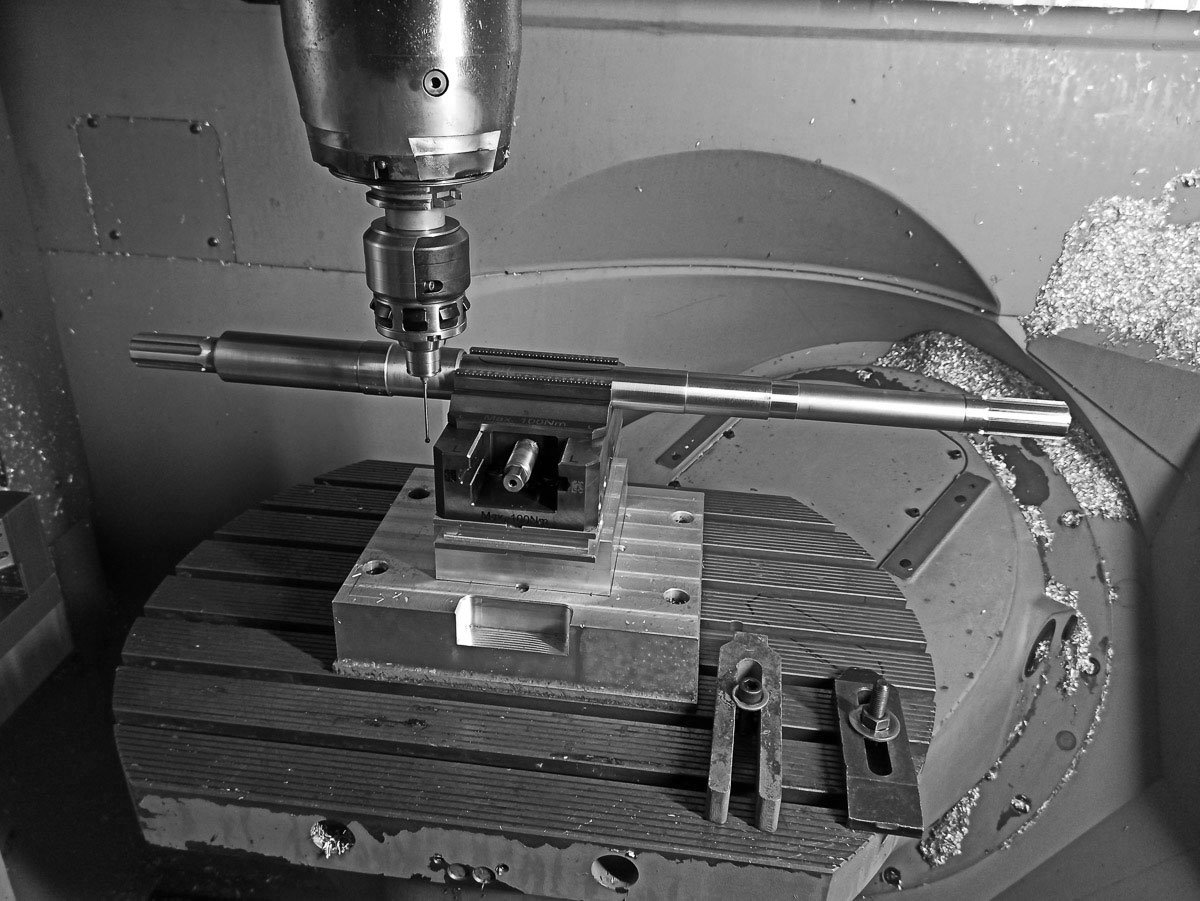

5axis CNC milling:

Deckel Maho DMU

70eVo linear

Travel dimensions (X/Y/Z): 750/600/520

A axis: 102deg

C axis: 360deg

3axis CNC milling:

Okuma space center

MA-500HA

Travel dimensions

(X/Y/Z):710/890/780